Installing the Barrier involves four main operations: Pile Driving, Joint Flushing, Joint Sealing, and the Quality Assurance & Quality Control program.

Pile Driving

Waterloo Barrier® sheet piles are installed using the same equipment and techniques as conventional products. Vibro equipment is suitable for most soil conditions although better results may be achieved with impact equipment in certain cohesive soils.

Joint Flushing & Joint Sealing

Once the piles have been installed to the required depth, the sealable cavities are flushed clean with pressurized water. The cavities are then tremie-grouted with clay-based, cementitious or polymer sealant, depending on the project requirements. Short-term installations can be sealed with an inflatable mechanical system.

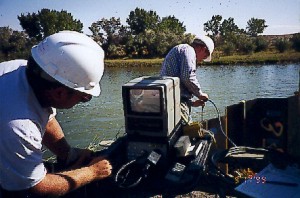

Quality Assurance & Quality Control Program

Potential leak paths through the Barrier are limited to the sealed joints and therefore the joints are the main focus of the quality control procedures. Pile driving, joint flushing and joint sealing operations are documented for each individual sheet pile. The sealable cavity is inspected to verify that it is open along its entire length prior to sealing. Examination by down-hole fibre optic video camera is an option.